- Very good image quality due to high resolution: 19,200 temperature measuring points ensure precise thermography. Infrared resolution of 160 x 120 pixels – via integrated SuperResolution Technology 320 x 240 pixels

- Visualize temperature differences from 0.12°C

- Critical temperature conditions are directly displayed via automatic hot-cold spot recognition

- The IFOV warner means the distance from the measurement object / measurement spot size is determined and the measurement spot is shown on the thermal image – you therefore avoid measurement errors because the camera shows you exactly what you can measure

- Pro software for image evaluation on the PC

- You can choose to save thermal images as JPEGs

Thermal imager – testo 865 (160 x 120 pixels)

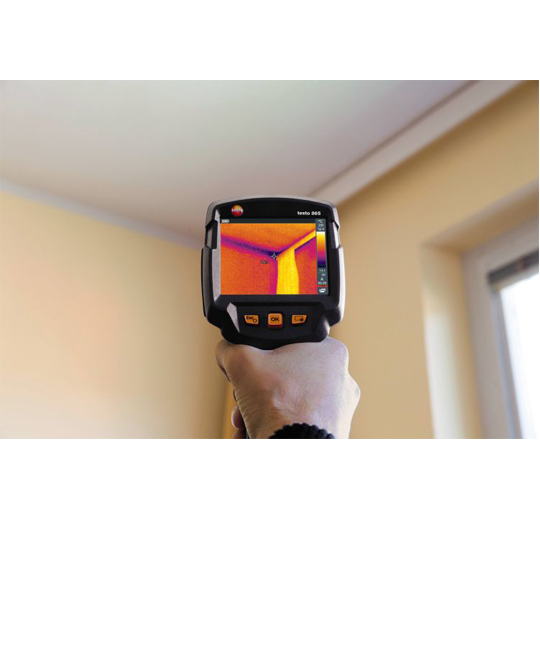

The testo 865 thermal imager offers professional technology and concentrates on functions which are needed in a contractor’s daily work. The testo 865 is a user-friendly thermal imager, optimized for fast and efficient work. With the testo ScaleAssist functions ensuring optimum setting of the thermal image scale for building thermography and the IFOV warner making sure you avoid measurement errors, you will always generate the perfect infrared image.

Areas of application of the testo 865 thermal imager

Detect leaks, identify overheated connections, pinpoint thermal bridges or detect structural defects. The testo 865 thermal imager is ideal for applications in daily maintenance and installation work in trade and industry. It enables time-saving quality assurance and ensures reliable production control.

Technical highlights of the testo 865 thermal imager

Ambient Condition |

|

|---|---|

| Operating temperature | -15 to +50 °C |

| Storage temperature | -30 to +60 °C |

| Air humidity | 20 to 80 %RH non-condensing |

| Housing protection class | IP54 |

| Vibration | 2G |

Image presentation |

|

|---|---|

| Display type | 8.9 cm (3.5") TFT, QVGA (320 x 240 pixels) |

| Display option | IR image only |

| Colours | 4 (iron, rainbow, cold-hot, grey) |

Imager equipment |

|

|---|---|

| Full screen mode | Included |

| JPEG storage | Included |

| Video streaming | via USB |

| Standard lens | 31 ° x 23 ° |

| Interface | USB 2.0 Micro B |

Imager storage |

|

|---|---|

| File format image | .bmt; .jpg; export option in .bmp; .jpg; .png; .xls; .csv |

| Storage device | Internal Memory (2.8 GB) |

Infrared image output |

|

|---|---|

| Spectral range | 7.5 to 14 µm |

| Infrared resolution | 160 x 120 pixels |

| Thermal sensitivity | 120 mK |

| Field of view | 31 ° x 23 ° |

| Minimum focus distance | <0.5 m |

| Geometric resolution (IFOV) | 3.4 mrad |

| SuperResolution (Pixel) | 320 x 240 pixels |

| SuperResolution (IFOV) | 2.1 mrad |

| Image refresh rate | 9 Hz |

| Focus | Fixed focus |

Measurement |

|

|---|---|

| Measuring range | -20 to +280 °C |

| Accuracy | ±2 °C, ±2 % of mv |

| Emissivity | 0.01 to 1 |

| Reflected temperature | manual |

Measuring function |

|

|---|---|

| Analysis function | Mean point measurement, hot/cold-spot recognition, Delta T |

| IFOV warner | Included |

| testo ScaleAssist | Included |

PC software |

|

|---|---|

| System requirements | Windows® 10; Windows® 8; Windows® 7 |

Physical specification |

|

|---|---|

| Dimensions | 219 x 96 x 95 mm |

| Weight | 510 g |

| Product-/housing material | PC – ABS |

Power supply |

|

|---|---|

| Battery type | Fast-charging, Li-ion battery can be changed on-site |

| Operating time | 4.0 h |

| Mains operation | yes |

Termovisores garantia |

|

|---|---|

| EU-/EG-guidelines | EMC: 2014/30/EU |

1. Preventive maintenance

- Fast detection of critical thermal status (so-called HotSpots) during continuing operation

- Avoid expensive damage, downtimes and fire risks on plants and machines

1.1. Electrical maintenance

- Test switching cabinets, electrical conditions, photovoltaic plants

- Evaluate heat status in low, medium and high voltage plants

1.2. Mechanical maintenance

- Identify wear on machines

- Test motors, bearings, shafts

2. Detecting structural defects and ensuring construction quality

- Detect potential building defects, prove quality and the implementation of construction measures without contact – with the help of thermal images

- Test air-tightness of windows and doors

- Locate insulation errors and cold bridges in a building shell

- Detect and visualize mould-risk areas

3. Easy checking of heating systems and installations

- test heating and air conditioning/ventilation systems: Use a thermal imager to identify irregularities in the temperature distribution quickly and easily

- Localization of the course of heating loops in underfloor heating systems