Featured Products

-

Air dust

-

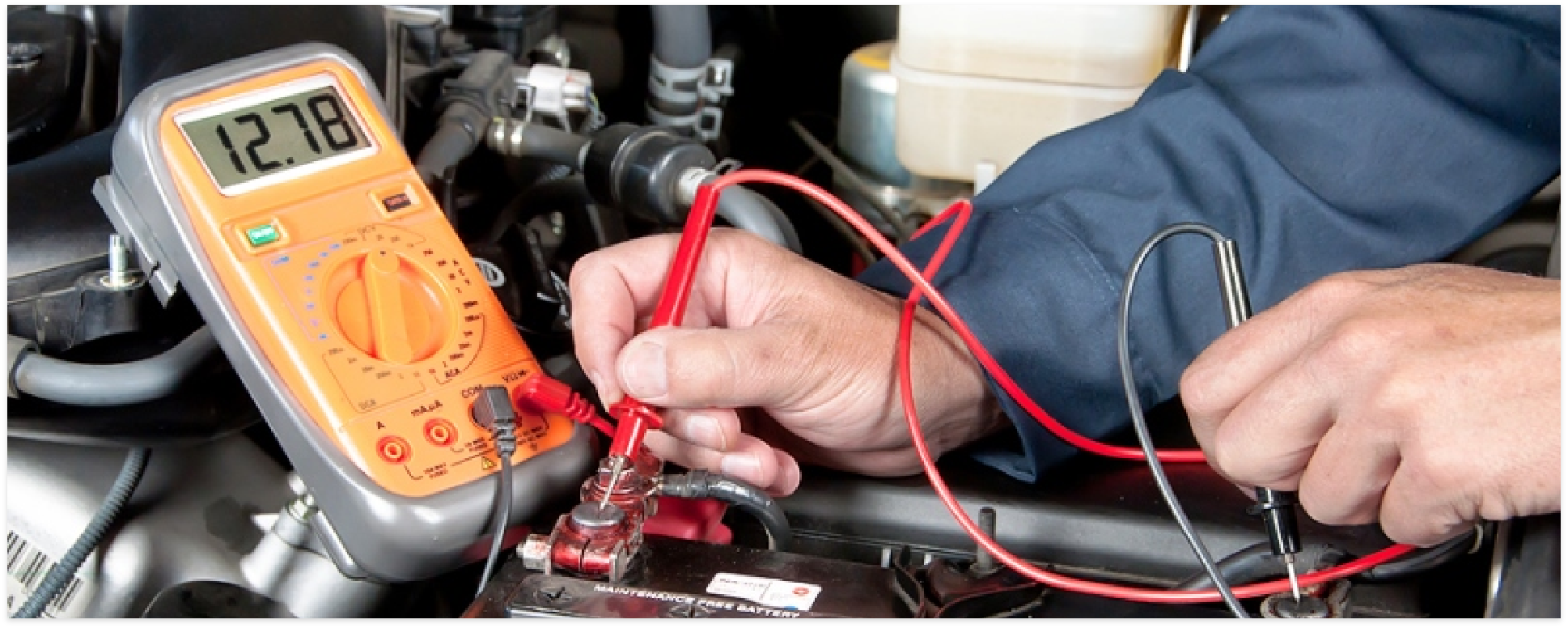

Energy survey

-

Vibration - Noise

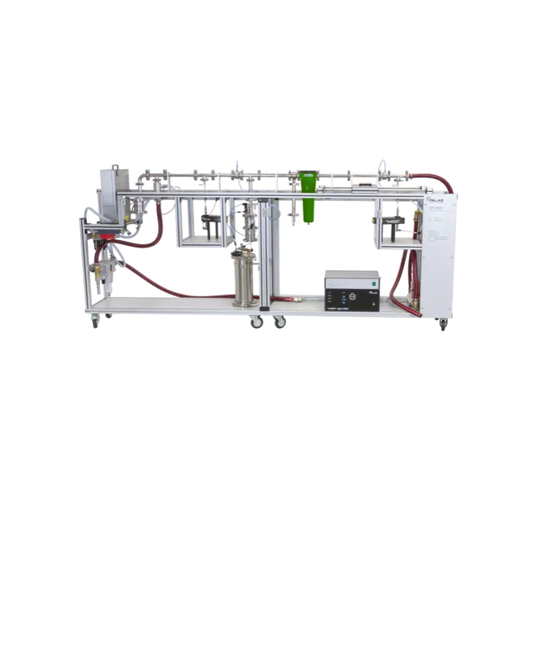

Hệ thống kiểm tra bộ lọc - DFP 3000

Compressed air filter testing system newly developed DFP 3000 provides fully automated measurements of fractionation efficiency for compressed air filters under overpressure up to 7 bar, providing better in-process results than ISO 12500.

U-SMPS 1050/1100/1200

Universal scanning mobility particle sizer for various applications (4 – 600 nm)

Fine Dust Monitoring Devices Fidas Frog

Battery powered, portable fine dust measurement device with detachable control panel, for outdoor, indoor and workplace measurements based on EN 481

Mask / respirator inspection system - Mas-Q-Check

The Mas-Q-Check was developed by Palas to subject protective masks to a quick, simple and yet meaningful test before use. A particle counting measurement device is used, which is able to detect efficiencies in the size range of viruses and bacteria. The system can also be used for training purposes as it immediately shows the efficiency of protective masks.

AQ Guard

AQ Guard is Measuring device for monitoring indoor air quality Measurement of dust concentrations starting at 150 nm (*1) incl. CO2 and tVOC for calculation of air quality and infection risk index.

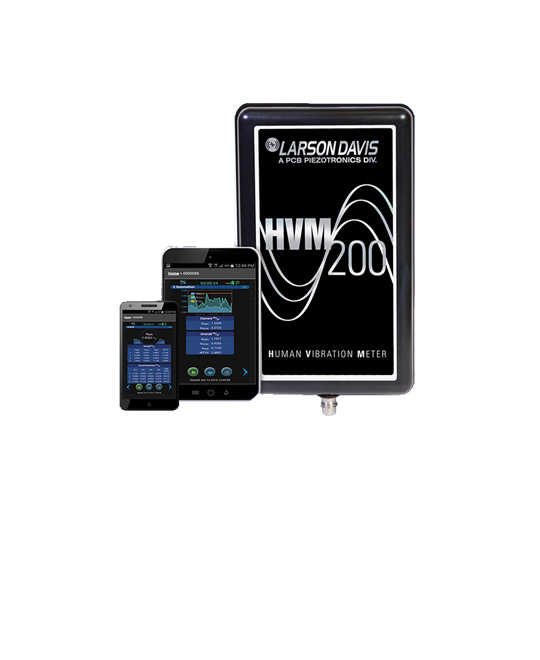

Human Vibration Meter - HVM200

The HVM200 is a small rugged vibration meter with built in Wi-Fi that can be used to measure hand-arm, whole body and general vibration. It includes the metrics and frequency weightings needed to measure human vibration. This 3 channel meter meets the requirements of ISO 8041:2005 and it is designed to measure per ISO 2631-1, 2 & 5 and ISO 5349 in support of the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Values (TLVs) and the directive 2002/44/EC.